Sustainability

Sustainable, Eco-Friendly & FSC certified wood

SUSTAINABLE HIGH PERFORMANCE WOOD

Ideal for windows, doors, cladding, decking and many more applications

Accoya® wood is a high performance wood. Created from sustainably-sourced wood, Accoya® undergoes a proprietary, non-toxic acetylation process that permanently modifies the wood to the core.

The result: an environmentally friendly solid wood with durability, dimensional stability and beauty that matches or exceeds even the best tropic hardwood.

Accoya® wood is sourced from sustainable sources, including FSC® and has class leading environmental credentials such as Cradle to Cradle™ Gold certification by the highly prestigious McDonough Braungart Design Chemistry (MBDC) organization.

Accoya® wood is perfect for demanding applications such as windows and doors, where it is important that tolerances are tight yet regardless of the conditions, they open year round. Accoya® is perfect for siding where wood’s natural beauty is desired, but sustainability and high performance are of the utmost importance. In decking, where it is important that boards do not warp, twist, bow split, Accoya® is up to the challenge.

We’d like to show you that Accoya® wood truly is a leading edge material that treads softly on the earth.

If you like to use wood in outdoor applications and are considering ways in which your projects can be more sustainable, achieve a lower carbon footprint and increased energy efficiency, Accoya wood may well be the answer you’ve been waiting for.

For More Information visit

Accoya Applications

High performance, Sustainable timber for your application.

A new world of high performance, sustainable and low maintenance applications are opened up by Accoya wood.

Accoya can be used in virtually any application because of its outstanding technical characteristics.

From large scale structural and cladding jobs to smaller scale domestic projects, Accoya has been used successfully.

It is also the material of choice for carpenters and craftsmen.

For More Information visit

Accoya General Fixings

For Accoya Fixings please view our SPAX page.

Accoya Speciality Fixings

Timber to metal or aluminium please visit our Anchormark page.

Accoya Properties Brochures

Accoya Properties

Accoya’s outstanding performance in the most demanding applications provides users with versatility to produce their athletically pleasing timber designs.

Key Features & Benefits

Superior Coating Performance

Accoya® wood’s superior coatings performance is primarily due to its outstanding dimensional stability. This effectively means that major coating systems can be used on Accoya® with significantly improved performance.

With Accoya wood, swelling and shrinkage is reduced by 70-80% and the resultant more stable surface allows coatings to adhere better. Dimensionally stable wood improves coatings life as paints and other film-forming coatings are not subjected to severe stretch and shrink cycles. In the end, the result is decreased maintenance frequency

Class 1 Durability

As ‘Class 1’ suggests, this is simply the best level of durability possible in wood. Whilst some wood species are naturally durable, natural durability is known to be a variable and inconsistent property.

Accoya wood, on the other hand, is consistently durable. The properties of every batch are analysed by standard scientific measurements after modification, enabling its durability to at least match and even exceed the performance of nature’s most durable species, including teak.

Additionally, durable woods tend to be slower growing species, whereas Accoya is made using fast growing, sustainably forested radiata pine, so old growth forests are not threatened or depleted to create Accoya.

Excellent Machinability & Ease of Fixing

Accoya wood is easy to machine and process manually, creating no challenges for product manufacturers and end users. Accoya wood can be fixed in the same way as other commonly used softwood species. As with most durable woods, Accoya contains a small amount of acid. It is therefore strongly recommended that corrosion resistant fixings, such as high quality stainless steel, are used.

The manufacturing process does not compromise the wood’s strength. In fact, the hardness of the wood is increased and because Accoya wood has a high strength to weight ratio, it is suitable for challenging applications – even heavy traffic road bridges.

Extreme Conditions

Accoya wood has been tested over prolonged periods in all types of weathering conditions – above ground, below ground and in freshwater – and has been proven to withstand even the toughest and most challenging of environments. Even after a prolonged period of immersion, Accoya window frames operate smoothly, without jamming.

For More Information visit

Accoya General Fixings

For Accoya Fixings please view our SPAX page.

Accoya Speciality Fixings

Timber to metal or aluminium please visit our Anchormark page.

ACCOYA PROPERTIES BROCHURES

Accoya Availability

Stock holding available in NSW, QLD, TAS and VIC

Accoya Rough Sawn

Subject to Availability

| WIDTH | THICKNESS |

|---|---|

| 100 | 25, 38, 50, 75, 100 |

| 125 | 25, 38, 50, 75 |

| 150 | 25, 38, 50, 75 |

| 200 | 25, 38, 50, 75 |

| 250 | 25, 38, 50 |

| 300 | 25 |

Accoya Finger Jointed

Subject to Availability

| WIDTH | THICKNESS |

|---|---|

| 150 | 50 |

| 200 | 50 |

For More Information visit

Accoya General Fixings

For Accoya Fixings please view our SPAX page.

Accoya Speciality Fixings

Timber to metal or aluminium please visit our Anchormark page.

About Accoya Brochures

About Accoya

Certified, Non Toxic modified wood.

Consistent Quality & Ease of Use.

Wood is a natural material and each piece is unique. This is partly what makes it so aesthetically pleasing and yet it can be a source of frustration and uncertainty when looking for guaranteed performance quality. However, with Accoya wood you can be sure of its consistent quality, durability and dimensional stability.

Wood acetylation is a process that has been studied by scientists around the world for more than eighty years. The Accoya wood production process combines this work with years of proprietary research and investment to deliver consistent results on a commercial scale. Unusually, the effectiveness of the process used to manufacture Accoya wood is measured after the wood has been produced, using an array of sophisticated and proven analytical techniques.

Each batch is analysed and Accoya wood always meets the requirements of Durability Class 1 for Use Classes 1-4 in accordance with EN 350-1 & EN 335-1.

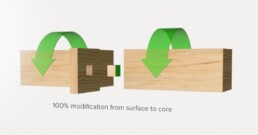

Because Accoya wood is modified all the way through, rather than just at the surface, when it is cut, planed or jointed there are no exposed unprotected surfaces in any dimension. This completely removes the need to apply additional chemical preservatives as is necessary with unmodified or envelope treated woods.

ACETYLATION PROCESS

Accoya is based upon acetylated wood technology, a process that has been studied by scientists around the world for more than 80 years.

This method of improving wood has been proven to deliver such superior performance that it has long been used as the “gold standard” against which other methods are measured.

The physical properties of any material are determined by its chemical structure. Wood contains an abundance of chemical groups called “free hydroxyls”. Free hydroxyl groups absorb and release water according to changes in the climatic conditions to which the wood is exposed.

This is the main reason why wood swells and shrinks. It is also believed that the digestion of wood by enzymes initiates at the free hydroxyl sites – which is one of the principal reasons why wood is prone to decay.

Acetylation effectively changes the free hydroxyls within the wood into acetyl groups. This is done by reacting the wood with acetic anhydride, which comes from acetic acid (vinegar when in dilute form).

When the free hydroxyl group is transformed to an acetyl group, the ability of the wood to absorb water is greatly reduced, rendering the wood more dimensionally stable and extremely durable.

Acetyl groups are already naturally present in all wood species. This means that the manufacturing process adds nothing into the wood that does not already occur within it.

The end product, Accoya® wood, does not add toxins to the environment. The effect of altering the wood’s chemical structure, as opposed to merely altering its chemical content, is to create an end product that is dramatically superior to its source species.

Accoya wood is modified right through the cross section whereas, by contrast, virtually all other treatments merely insert chemicals (such as oils, ammonia or metal compounds) into the wood, improving durability, to a degree, but not dimensional stability.

For More Information visit

Accoya General Fixings

For Accoya Fixings please view our SPAX page.

Accoya Speciality Fixings

Timber to metal or aluminium please visit our Anchormark page.

About Accoya Brochures

Touchwood

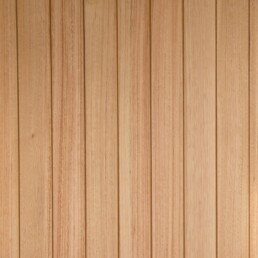

TouchWood is a versatile tongue and groove panelling product.

TouchWood has been created to make the warmth and beauty of natural timbers accessible to a wider range of interior designs and budgets.

Looks good. Feels good. Does good.

Using natural materials in design and décor is proven to have a positive effect on wellbeing. Known as biophilic design, it reconnects people with nature, can help reduce stress and improve our emotional state. TouchWood veneer panelling is a way to bring native wood within everyone’s reach, in more ways than one.

Sustainable

Britton Timbers sources all of its Tasmanian timber from the sustainably-managed and PEFC certified temperate forests of the north-west region of the state.

Britton Timbers is Forest Stewardship Council® (FSC-C113479) Chain of Custody certified for its range of imported timbers from Scientific Certification Systems – one of the world’s leading FSC® certifiers.

Sustainability is also achieved through compliance with the provisions of the Forest Practices Code and the Tasmanian Forests Agreement (TFA). “Any customer buying products from Britton Timbers or products manufactured from timber supplied by Britton Timbers and sourced from Tasmania’s public native forests, can do so in the full confidence that it is produced in accordance with the TFA”.

The 9mm moisture resistant MDF board backing (in natural or black) with Blackwood or Tasmanian Oak veneer face gives the illusion of solid timber VJ panelling. And the good stuff doesn’t end there. It is also a sustainable product that utilises native timber veneers from PEFC certified forests.

Saving money and time on both materials and installation, TouchWood can be used to transform an existing space by fixing it directly onto plasterboard or specified in new projects at scale.

Perfect for off-the-wall design.

Designers don’t limit their imagination to only using TouchWood as a wall panelling. By combining their creativity and TouchWood’s easy installation and effortlessly versatile ergonomics, they use it to clad ceilings, bedheads, cupboards and counterfronts.

It is equally at home fixed vertically or horizontally; in modern interiors or more traditional settings and can be left uncoated or finished with wax, oil or polyurethane in matt, gloss or satin finish.

Technical Specifications

| Sheet size |

|

| Materials |

|

| VJ width | (distance between grooves) is 100mm |

| Panel jointing | Panels are joined with a tongue and groove system |